ENG

ENG- Branchen

- Finanzen

Nearshore-Softwareentwicklung für den Finanzsektor – sicher, skalierbar und Compliance-gerechte Lösungen für Banking, Zahlungsverkehr und APIs.

- Einzelhandel

Softwareentwicklung für den Einzelhandel – E-Commerce, Kassensysteme, Logistik und KI-gestützte Personalisierung durch unsere Nearshore-Engineering-Teams.

- Verarbeitende Industrie

Nearshore-Softwareentwicklung für die Industrie – ERP-Systeme, IoT-Plattformen und Automatisierungstools zur Optimierung industrieller Abläufe.

- Finanzen

- Was wir tun

- Services

- Technologien

- Kooperationsmodelle

Kooperationsmodelle passend zu Ihren Bedürfnissen: Komplette Nearshoring Teams, deutschsprachige Experten vor Ort mit Nearshoring-Teams oder gemischte Teams mit unseren Partnern.

- Arbeitsweise

Durch enge Zusammenarbeit mit Ihrem Unternehmen schaffen wir maßgeschneiderte Lösungen, die auf Ihre Anforderungen abgestimmt sind und zu nachhaltigen Ergebnissen führen.

- Über uns

- Wer wir sind

Wir sind ein Full-Service Nearshoring-Anbieter für digitale Softwareprodukte, ein perfekter Partner mit deutschsprachigen Experten vor Ort, Ihre Business-Anforderungen stets im Blick

- Unser Team

Das ProductDock Team ist mit modernen Technologien und Tools vertraut und setzt seit 15 Jahren zusammen mit namhaften Firmen erfolgreiche Projekte um.

- Wozu Nearshoring

Wir kombinieren Nearshore- und Fachwissen vor Ort, um Sie während Ihrer gesamten digitalen Produktreise optimal zu unterstützen. Lassen Sie uns Ihr Business gemeinsam auf das nächste digitale Level anheben.

- Wer wir sind

- Unser Leistungen

- Karriere

- Arbeiten bei ProductDock

Unser Fokus liegt auf der Förderung von Teamarbeit, Kreativität und Empowerment innerhalb unseres Teams von über 120 talentierten Tech-Experten.

- Offene Stellen

Begeistert es dich, an spannenden Projekten mitzuwirken und zu sehen, wie dein Einsatz zu erfolgreichen Ergebnissen führt? Dann bist du bei uns richtig.

- Info Guide für Kandidaten

Wie suchen wir unsere Crew-Mitglieder aus? Wir sehen dich als Teil unserer Crew und erklären gerne unseren Auswahlprozess.

- Arbeiten bei ProductDock

- Newsroom

- News

Folgen Sie unseren neuesten Updates und Veröffentlichungen, damit Sie stets über die aktuellsten Entwicklungen von ProductDock informiert sind.

- Events

Vertiefen Sie Ihr Wissen, indem Sie sich mit Gleichgesinnten vernetzen und an unseren nächsten Veranstaltungen Erfahrungen mit Experten austauschen.

- News

- Blog

- Kontakt

04. Juni 2025 •7 minutes read

How nearshoring solves the software talent gap for Sweden’s manufacturing companies

ProductDock

From machinery to automotive to electronics, Sweden’s manufacturing industry is increasingly relying on advanced software to improve efficiency and sustainability. In fact, we can confidently say that software development is no longer just supporting manufacturing; it is driving it.

Today, custom-built applications power nearly every part of the manufacturing process. From predictive maintenance and real-time production monitoring to supply chain optimization, software plays a central role in how modern factories operate. Despite the fact that technologies such as IoT, AI and robotics have become essential in industrial operations in Sweden, the country is facing a shortage of qualified software developers, particularly those who understand manufacturing-specific needs.

That’s why manufacturing companies in Sweden are turning to nearshoring development teams. But what exactly does nearshoring bring to the manufacturing industry?

Let’s find out!

The talent gap challenge in Sweden

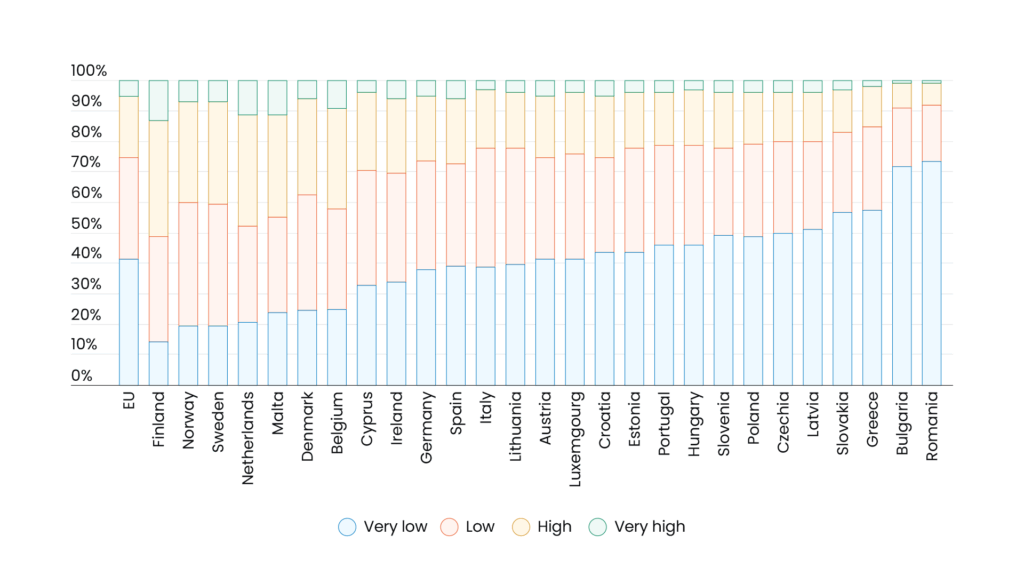

Sweden is one of the most technologically advanced countries in the world, which is illustrated by the country’s high ranking in the EU’s Digital Intensity Index. The rapid adoption of IoT, advanced robotics, custom software and AI in manufacturing has significantly increased the demand for skilled professionals, not just on the production floor but also within software development teams responsible for modernizing and maintaining these evolving systems.

Source: Market study: The Swedish market for IT services, Open Trade Gate Sweden, October 2024

With 78% of manufacturers either having implemented or planning to invest in supply chain software to improve supply chain planning, collaboration between suppliers and operational visibility, the shortage of qualified talent has become a major concern. In fact, 76% of Swedish companies report difficulty finding individuals with the right skills, which is nearly double the figure from a decade ago.

The talent shortage is especially evident in areas like engineering, IT and data, fields that are critical for the digitalization of manufacturing. As a result, salaries in these sectors are rising, and the competition for skilled professionals is becoming more intense. Since 2022, salaries for software developers with just three years of experience have jumped by 12%. This makes it harder for small and mid-sized manufacturers to compete with larger companies that can offer higher pay and better working conditions.

To keep up, many Swedish manufacturers are turning to outsourcing, more specifically, nearshoring. By partnering up with software developers in nearby European countries, they can quickly access skilled talents. Nearshoring provides cost efficiency, overlapping time zones and access to professionals who are not only tech-savvy but also understand the specific needs of the manufacturing sector.

What nearshore software development brings to Sweden’s manufacturing market

Nearshoring has become one of the most convenient and effective outsourcing strategies for Swedish manufacturers. Compared to offshore teams, nearshore partners are much closer to home, not just in terms of geography but also in culture, language and working hours. This makes day-to-day collaboration smoother and more efficient.

At the same time, compared to hiring locally, nearshoring is often more flexible, easier to scale, and more cost-effective. It also gives manufacturers access to the latest technologies and innovative practices from across Europe, bringing real value to Swedish consumers and giving companies a chance to stand out in a competitive market.

For Sweden’s manufacturing sector, nearshoring offers several key benefits:

Faster time to market

In manufacturing, delays mean lost revenue, dissatisfied consumers and giving competitors the upper hand. Whether it’s launching a new product, upgrading a factory system or digitizing a supply chain, speed is critical.

Nearshore teams are often able to get started much faster than in-house hires. By avoiding the lengthy and costly recruitment and onboarding processes, manufacturers can accelerate project kick-off and move directly into development. Working in the same or similar time zones also enables real-time communication and faster decision-making, both of which are essential in a fast-paced manufacturing environment. Nearshore developers can collaborate directly with Swedish product managers, engineers and operations teams during regular working hours. This close coordination helps speed up iterations, testing and approvals, ultimately reducing time to deployment.

Maria Strömsdörfer, a product owner at a German automotive company, emphasized how quickly her nearshore team became a valuable part of the company:

“We’re impressed by how quickly they integrated into our team. They’re also very transparent, and having them on board has been very beneficial for us because they’re experienced in a lot of technologies.”

Access to a larger talent pool

As manufacturing becomes increasingly digitalized, the shortage of skilled professionals is no longer just an HR issue, it’s a strategic risk that can delay innovation, slow growth, and reduce competitiveness.

Nearshore software development helps solve this challenge by opening access to broader tech hubs in Europe. Developers and engineers from countries such as Portugal, Germany, Serbia, and Bosnia and Herzegovina bring not only deep technical expertise but also hands-on experience in manufacturing specific technologies.

These teams are well-versed in agile methodologies and know how to work closely with clients of different sizes and teams. Their approach is structured, collaborative and focused on delivering high-quality, scalable solutions.

A good example of this is KAMAX Group, a leading producer of high-strength fasteners for the automotive industry. When they partnered with a nearshore team, they cited the team’s structured approach as a key decision factor:

“We checked different possibilities, but their methodology convinced us. The nearshore team put a lot of effort into the pre-interviews, giving us a good image of how it would be to work with them, from the business requirements to the final solution.”

By tapping into a wider talent pool, manufacturers gain access to fresh perspectives that help them innovate faster and stay competitive.

Flexibility in scaling teams

In the manufacturing industry, the demand for technical expertise can fluctuate depending on the phase and scope of a project. Nearshoring offers manufacturers the flexibility to scale teams up or down based on real-time needs without long-term commitments or overhead. For example, a company might start with a smaller team during early development, expand the team as it moves toward product launch, and then scale back again for ongoing maintenance and support. This kind of agility is difficult to achieve with internal teams. Scaling in-house often comes with high costs tied to recruitment, onboarding and training.

This approach proved effective in the KAMAX Group mentioned earlier. The company initially worked with a team of four developers and a UI/UX designer. In later phases, the workload changed, so the team was adjusted to two developers, a scrum master, and a part-time UX designer. This smooth transition ensures efficiency without wasting resources.

High availability and reliability

System downtime or technical issues in factories can do more than just slow down productivity; they can lead to missed deadlines and, in some cases, pose serious safety risks. For example, a failure in a real-time monitoring system could lead to undetected machinery malfunctions, causing production delays, increased repair costs or even more severe safety hazards for employees.

This is why high availability and reliability from a software development team are critical in the manufacturing industry.

As nearshore software partners operate in tech ecosystems with strong infrastructure with well-established quality standards, manufacturers can count on consistent delivery and dependable support throughout the entire development lifecycle. Also, nearshore teams work in the same or similar time zone as Sweden, enabling immediate support and minimizing operational disruptions.

Đorđe Mijailović, a full-stack developer working on business analytics tools for a global leader in the automotive industry, highlights the importance of reliability and team alignment in manufacturing projects:

“Over these four years, there have been many moments to be proud of, both as a team and individually. But the most important lesson was realizing how much can be achieved with just 4-5 people if they are synced in ideas and goals. We learned a lot in different areas of our work, delivered measurable results, like money saved for the client, and kept almost zero bugs along the way.”

Strategies for successfully nearshoring software development in manufacturing

Choose the right nearshore partner

Choosing the right nearshore partner is an important first step toward a successful collaboration. Look for a company with a proven track record in both the manufacturing industry and nearshoring. Real client reviews on platforms like Clutch can be especially helpful, as they offer insight into actual experiences, communication practices and delivery performance. Also, pay attention to the countries your IT vendor operates in, their years of experience, and the case studies shared on their website.

Ensure clear communication channels

Smooth collaboration with a nearshore team relies on effective communication. It is important to know what kind of communication tools the IT vendors use and how and when you will interact with the development team. Check if they work with tools such as Jira, Trello, and Slack and make sure there are clear procedures for status updates, feedback loops and decision making. Structured communication helps avoid misunderstandings and ensures the project stays on track.

Check ethical and legal business practices

Swedish manufacturing companies are known for upholding high ethical and legal standards, and the same should apply to their nearshore partners. When choosing a nearshore partner, ensure their business practices align with your company’s values and compliance requirements. Look for recognized certifications that demonstrate the partner follows best industry practices and can be trusted to handle sensitive information and complex systems with integrity.

Conclusion

With Sweden’s manufacturing sector projected to generate SEK 160-220 billion annually by the end of 2025 through the wider adoption of digital technologies, partnering with a skilled software development team it’s a strategic move to stay competitive.

Nearshoring offers Swedish manufacturing companies a smart, effective way to meet the growing demand for tech expertise. However, to fully realize its benefits, it’s important to choose the right partner, establish clear communication, and align on shared values such as quality, transparency and ethical business practices.

Looking ahead, collaborating with experienced tech teams across Europe can help manufacturers improve production capacity, reduce downtime and optimize resource utilization, laying a solid foundation for sustainable growth.